Innovative Solutions

Driven to Provide Value to Your System

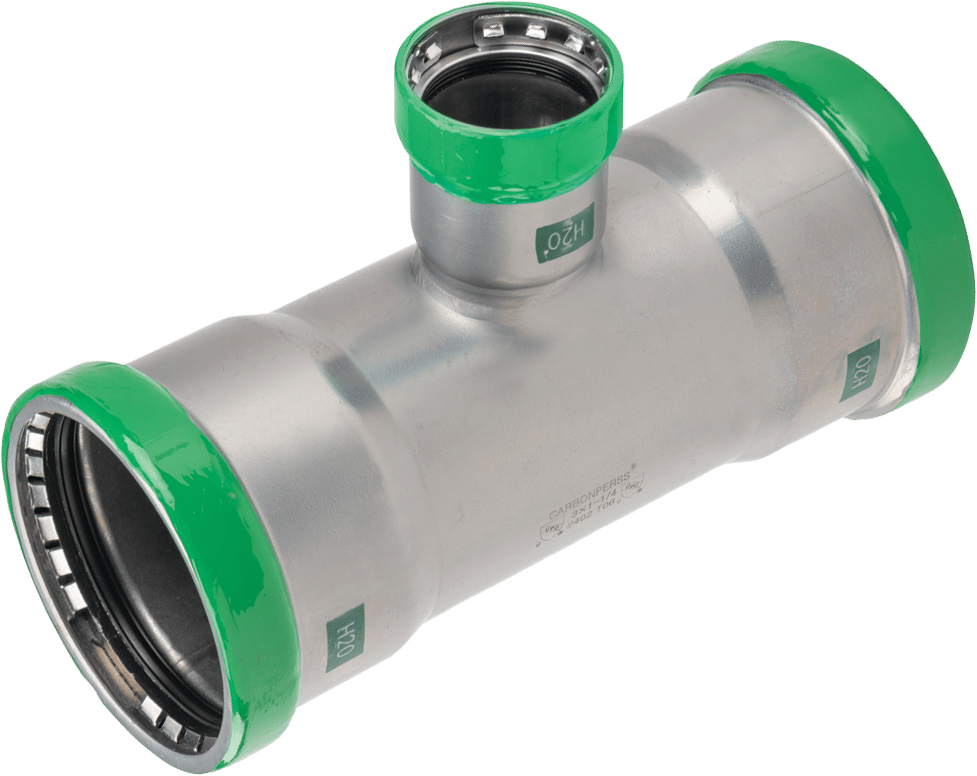

Large OD (2-1/2” - 4”) NEW!

Size Range: 1/2” - 4”

Temperature Range: -40°F to 300°F (-40°C to 148°C)

Working Pressure Range: From Full Vacuum to 250 psi (17.2 bar) for Water

Sealing Element Color: Black

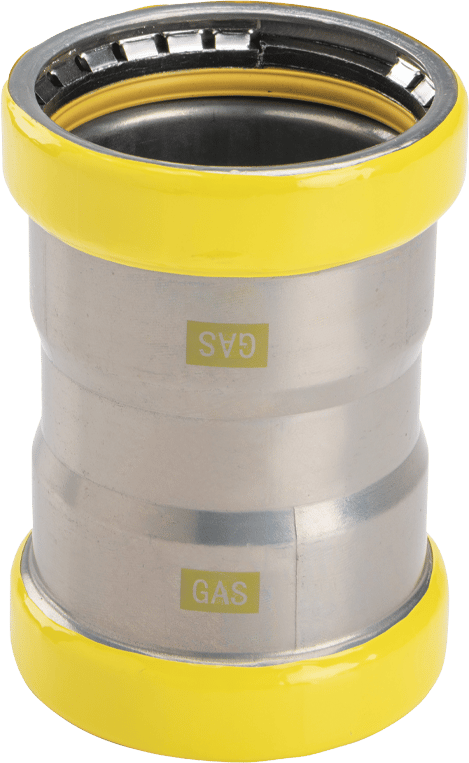

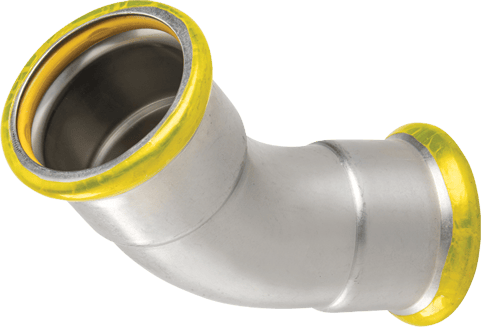

Size Range: 1/2” - 4”

Temperature Range: -40°F to 200°F (-40°C to 93°C)

Working Pressure Range: From Full Vacuum to 125 psi (8.6 bar) for Gas

Sealing Element Color: Yellow

FKM see below...

FKM Sealing Element NEW!

*

Size Range: 1/2” – 4”

Temperature Range: 14°F to 293°F (-10°C to 145°C)

Working Pressure Range: From Full Vacuum to 200 psi (13.7 bar) for Industrial

Sealing Element Color: Brown

*available upon request

HNBR

EPDM

Watch Our Brief Video

CarbonPress® Fittings

Leak Before Press Technology

Zn-Ni Plating

Approved Applications

Color-Coded Box, Bag, and Ring

Certifications, Codes, and Standards

Engineered sealing elements are designed to leak before they are pressed, giving a visual identification of a connection that has not been pressed.

Made from ASTM A420 Carbon Steel with Zn-Ni plating. ASTM A420 has excellent corrosion resistant properties.

Used in several applications including: fluids, water, gases, oil & lubricants. Some specific examples include: hydronic heating, chilled water, low-pressure steam applications, carbon dioxide, engine oil, and more.

The box, bag, and ring are color-coordinated to the sealing element for ease of receipt, identification, and safe installation for the application.

Certifications – IAPMO Z 1117 (EPDM & FKM); IAPMO/ANSI LC 4/CSA 6.32 (HNBR)

Codes & Standards – ASME B31.1 Power Piping; ASME B31.3 Process Piping; ASME B31.9 Building Service Piping; CSA B149.1 Natural Gas and Propane Installation Code; IAPMO Uniform Mechanical Code (UMC); IAPMO Uniform Plumbing Code (UPC).

Explore More CarbonPress® Benefits & Features

15-Year Limited Warranty on Fittings

IPS (Iron Pipe Size)

For use with Steel pipes conforming to ASTM A53, A106, A135, A795 (schedule 10 to 40) and black iron, epoxy coated and galvanized steel.

Grab ring deforms and grips outside diameter of pipe when pressed, securing the fitting and preventing movement during the pressing process.

Over 400 SKU's

Order CarbonPress® Today

How CarbonPress® Systems Benefit You

Streamlining Project Planning & Execution

BIM/Revit files for our press portfolio are available to download and use in the design of your systems.

Press systems are designed to provide the same quality and reliable pipe joint as other connection technologies while reducing the time to complete the joint; therefore, reducing the man-hours required for the entire project.

Innovation with Design in Mind to Save Time, Money & Labor

Training at Every Stage of the Process with Your Success in Mind

Each member of our sales & engineering team is qualified to provide job site product and installation training. This ensures that your experience with our press systems is a trouble-free experience.

Leveraging previous successful installations within a vertical market, or with an installer, helps to expedite growth of our wholesale distribution partners as we build those relationships together.

Supporting Distribution Growth Strategies Through Vertical Market Relationship Building

Click on the plus signs for more

From planning to training through to distribution, CarbonPress® provides value through innovative solutions.

Most Comprehensive

Product Offering

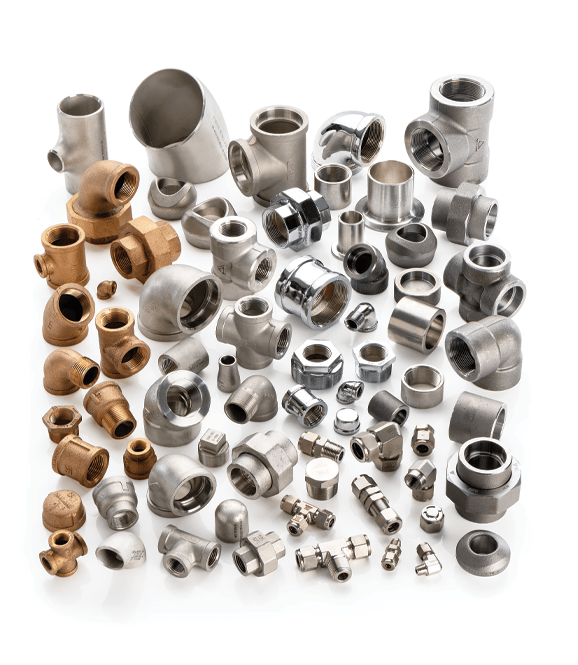

Merit Brass has a rich history of offering the most comprehensive flow control and piping connection technology. Our goal is to make the Merit Experience for our customers seamless by bundling a complete line of consistent, high-quality piping products, flow control devices, and piping system solutions.

Merit Brass features a full range of:

Press Products from Merit Brass

Legacy Products from Merit Brass

Get Your Connections Today

- Size Range: ½" – 2"

- Sealing Elements: EPDM (Water) & HNBR (Gas), and FKM (Industrial)*

- Operating Pressure: From Full Vacuum to 300 psi

- Temperature Range:

EPDM Fittings & Valves: -4°F to 230°F (-20°C to 110°C)

HNBR Fittings: -31°F to 248°F (-35°C to 120°C)

HNBR Valves: -13°F to 248°F (-25°C to 120°C)

FKM Fittings & Valves: -4°F to 356°F (-20°C to 180°C) - 15-Year Limited Warranty on Fittings and 5-Year Limited Warranty on Valves

- IPS (Iron Pipe Size)

- Mates with S5 & S10, 304 & 316 Stainless Steel Pipe

- Over 325 SKU's

Order StainlessPress® Today

*FKM available upon request

- Size Range: ½" – 4" (Fittings) and ½" – 2" (Valves)

- Sealing Elements: EPDM (Water)

- Operating Pressure: From full vacuum to 300 psi

- Temperature Range: 0°F to 250°F

(EPDM Fittings & Valves) - 50-Year Limited Warranty on Fittings and 5-Year Limited Warranty on Valves

- CTS (Copper Tube Size)

- NSF 61 on Fittings

- Over 350 SKU's

Order CopperPress® Today

DOWNLOAD OUR LINE CARD

REGISTER TO ORDER ONLINE

REQUEST A TRAINING

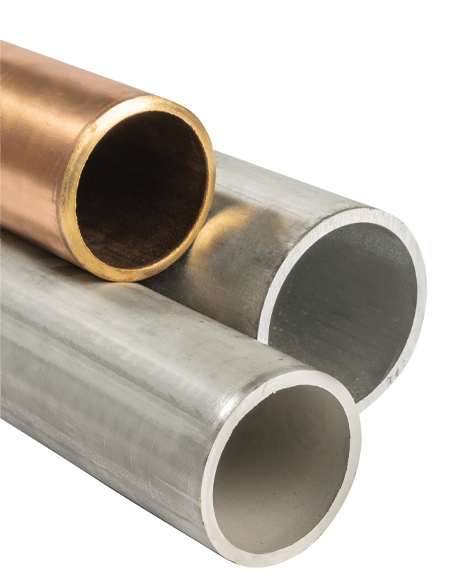

Order Pipe Today

Stainless Steel Pipe

304/L & 316/L Welded

- Schedule 10 (Standard)

- Schedule 40 (Standard)

- Schedule 80 (Extra Heavy)

304/L & 316/L Seamless

- Schedule 40 (Standard)

- Schedule 80 (Extra Heavy)

Brass Pipe

- Schedule 40 (Standard)

- Schedule 80 (Extra Heavy)

- Schedule 40 (Light Annealed)

Chrome-Plated Brass Pipe

- Schedule 40 (Seamless)

Aluminum Pipe

- Schedule 40 (Seamless; Standard)

Order Pipe Nipples Today

Stainless Steel Pipe Nipples

- 304/L & 31/L

- Schedule 40 (Standard)

- Schedule 80 (Extra Heavy)

- Welded & Seamless

- Pigtails/Syphons

Brass Pipe Nipples

- Schedule 40 (Standard)

- Schedule 80 (Extra Heavy)

- Pigtails/Syphons

Chrome-Plated Brass Pipe Nipples

- Schedule 40 (Standard)

- Hospital (Special Order)

Aluminum Pipe Nipples

- Schedule 40 (Standard)

- 6061-T6

Order Fittings Today

Stainless Steel Fittings

- 150# Fittings (Non-China Available, ISO & MSS SP-114 Patterns)

- 1000# Barstock Fittings

- 3000# Fittings (Socket Weld, Threaded, and Threaded x Socket Weld)

- 6000# Fittings (Socket Weld)

- Buttweld Fittings (China & Non-China)

- Tube Fittings

Brass Pipe Fittings

- Domestic (Leaded & Lead-Free)

- Import (Leaded & Lead-Free)

- Barstock (Leaded & Lead-Free)

Chrome-Plated Brass Pipe Fittings

- Domestic (Leaded & Lead-Free)

- Import (Leaded & Lead-Free)

Forged Carbon Steel Fittings

- 2000# (Threaded)

- 3000# (Socket Weld, Threaded, and Threaded x Socket Weld)

- 6000# (Threaded)

- Outlets (Threaded, Socket Weld, and Buttweld)

CarbonPress® Fittings

- EPDM, HNBR, FKM*

*FKM available upon request

CopperPress® Fittings

- EPDM

StainlessPress® Fittings

- HNBR, EPDM, and FKM*

*FKM available upon request

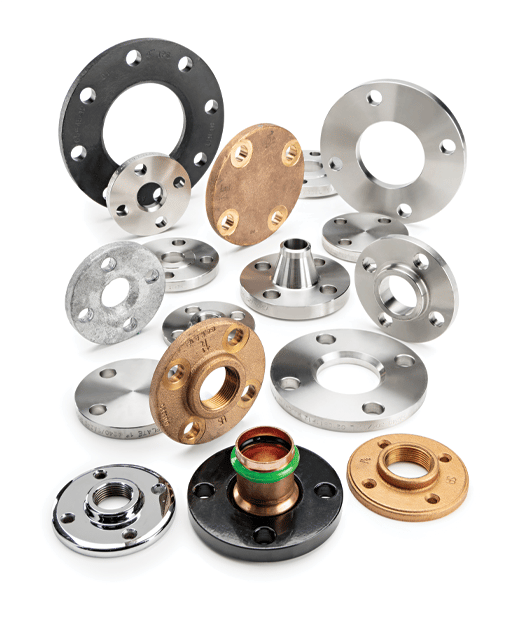

Order Flanges Today

Stainless Steel Flanges

- ANSI

- MSS

- 150 LB & 300 LB

- Weldneck, Blind, Threaded, Slip-On, Socket Weld, Lap Joint

- Plate (Tube OD Slip-On, Blind, IPS Slip-On Bevel x Square, and IPS Sip-On Square x Square)

Brass Flanges

- Domestic (Leaded & Lead-Free)

- Import (Leaded & Lead-Free)

- Class: 150, 250, and 300

Chrome-Plated Brass Pipe Flanges

- Floor

Ductile Iron Flanges

- Standard

- Galvanized

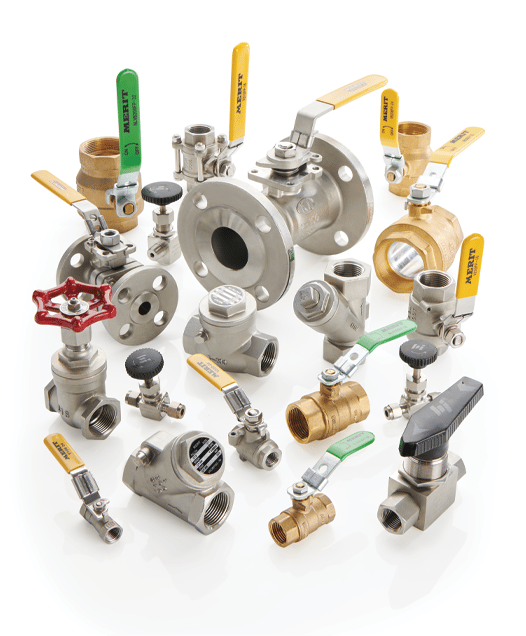

Order Valves Today

Stainless Steel Valves

“K” Series – Vietnam

- 1-Piece Ball Valve

- 2-Piece Ball Valve

- 3-Piece Ball Valve

“V” Series – Taiwan

- 1-Piece Ball Valve

- 2-Piece Ball Valve

- 3-Piece Ball Valve

- Gate Valve

- Swing Check Valve

- Wye Pattern Swing Check Valve

- Y-Strainer

Instrumentation

- Ball Valve

- Regulating Needle Valve

- Vee-Stem Needle Valve

StainlessPress®

- 2-Piece Ball Valve

Brass Valves

- 2-Piece Ball Valve (Leaded & Lead-Free)

CopperPress® Valves

- 2-Piece Ball Valve

Order Thread Tape Today

Stainless Steel PTFE Thread Tape

- UL Listed Threaded Sealant 561R

- Meets Military Specification MIL-T-27730A

- Nickel Coated

- ½” x 260”

- ¾” x 260”